An engaging and accessible e-learning program designed to improve our clients’ Performance, Safety & Reliability; the central components of successful operations.

Process Unit Basics is a comprehensive, 37 module program covering the Process Units found in a typical fuels refinery. The program is split into 11 sub-programs covering the 11 main Process Units; each comprising a varying number of modules.

Fluidized Catalytic Cracking (FCC) Advanced is an 8 module program that delves deeper into the complexities of the FCC – in particular the hydraulic & thermal relationships in the Reactor-Regenerator system. FCC Advanced is suitable for senior operators and graduate process engineers.

The aim of the Process Unit Basics program is to familiarize trainees with common Process Units they are likely to encounter in their plant and provide a solid foundation for assignment to a particular unit.

The first program, ‘Refinery Orientation’ teaches the trainee about the Overall Refinery Processing Configuration, describing the function of each Process Unit, the Product Slate, Unit Operations & Hydrocarbon Chemistry. For each process unit, the program addresses the following:

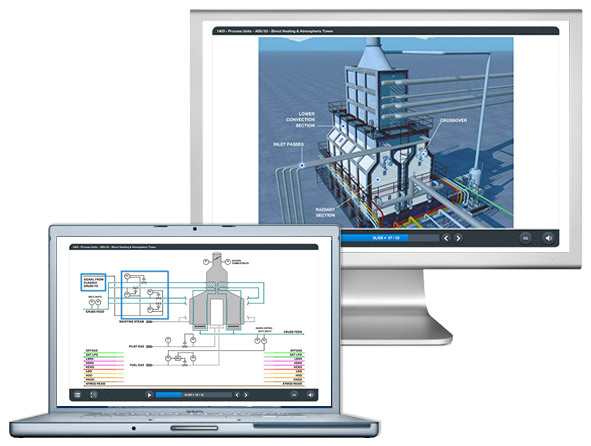

The program utilizes animated Process Flow Diagrams (PFDs) and Process Flow Control Diagrams (PFCDs) to walk the trainee through the process, facilitating trainee understanding of the process flows and process controls while simultaneously familiarizing trainees with reading and understanding PFDs and PFCDs in general.

An important theme of the program is the optimization of throughputs, yields, conversions and product qualities, while at the same time minimizing operating costs, reducing/eliminating production, inventory, equipment, energy & environmental losses.

The Process Units program comprises the following programs/modules:

All our e-learning programs are supported by modular assessments to allow you to monitor trainee attainment

PSR can provide e-learning programs in SCORM 1.2, SCORM 2004 or AICC formats. These can be hosted in your LMS, or we can host for you

Our modules are built with HTML5 rather than Flash, which means they are future-proof and work on mobile devices

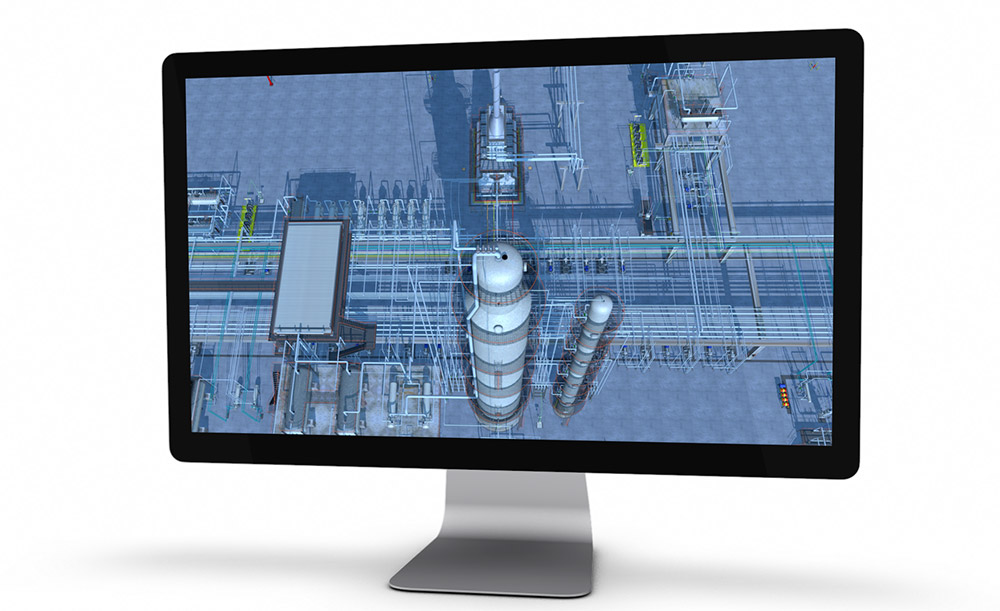

PSR deliver engaging and accessible training content that combines expert-level technical detail with 3D multimedia to communicate ideas clearly and effectively.

Our comprehensive library of hundreds of e-learning modules are targeted at the oil refining, oil & gas, petrochemical, chemical and energy industries. The modules can be purchased off-the-shelf, or can be customized to meet your needs.

Visit our homepage for more details, or contact us using the details below.

Contact us for more information on this and our other training programs

By continuing to use the site, you agree to the use of cookies. more information

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.